Auswahl eines DC/DC-Wandlers für Bahnanwendungen

21. Juni 2022 von Ron Stull – Lesezeit: 7 Minuten

Stromversorgung für moderne Bahnanwendungen

In der Vergangenheit war der 110-V-Akku in der Hauptlokomotive die Quelle der Gleichstromversorgung für die meisten elektrischen Bahnanwendungen. Das bedeutete, dass für die Beleuchtung der Waggons Kabel über die gesamte Zuglänge verlegt werden mussten.

Da der Akku auch an Schaltgeräte, Relais und andere schwere elektrische Lasten wie Anlasser angeschlossen war, kam es regelmäßig zu Spannungseinbrüchen und Spannungsspitzen sowie zu elektromagnetischen und Hochfrequenzstörungen (EMI/RFI) auf dem Kabel. Die Passagiere bemerkten diese Auswirkungen kaum, abgesehen davon, dass sich die Beleuchtungsstärke im Abteil gelegentlich änderte.

Moderne Züge sind technisch viel ausgereifter als ihre Vorgänger und verfügen jetzt über viele fortschrittliche Sicherheitsfunktionen, die mehrere Niederspannungssensoren und -aktoren verwenden. Darüber hinaus erwarten Bahnreisende heute Annehmlichkeiten wie Klimaanlagen, drahtlose Kommunikation und hochentwickelte Infotainment-Funktionen. Die Gewährleistung von Sicherheit und Komfort wäre ohne die Verfügbarkeit mehrerer Stromversorgungen mit konstanter Gleichspannung, die nicht durch externe elektrische Störquellen beeinträchtigt wird, nicht möglich. Dieser Blog-Beitrag befasst sich mit einigen der spezifischen Anforderungen für den Einsatz von DC/DC-Wandlern in Bahnanwendungen.

Normen für Bahnstrom

Die Norm EN 50155 – Bahnanwendungen – elektronische Einrichtungen auf Schienenfahrzeugen gilt für elektrische Geräte, die an die Bahnindustrie geliefert werden, und wurde von den meisten Herstellern von Bahnausrüstungen übernommen. Sie bezieht sich auf batteriebetriebene Systeme und Niederspannungsstromversorgungen, die direkt (oder indirekt) mit dem Kontaktsystem verbunden sind, und deckt die Anwendungen Steuerung, Einstellung, Schutz und Versorgung ab. DC/DC-Wandler in elektronischen Geräten für den Einsatz in Fahrzeugen müssen die EN 50155 in jeder der folgenden Hinsichten einhalten:

Eingangsspannungsbereich

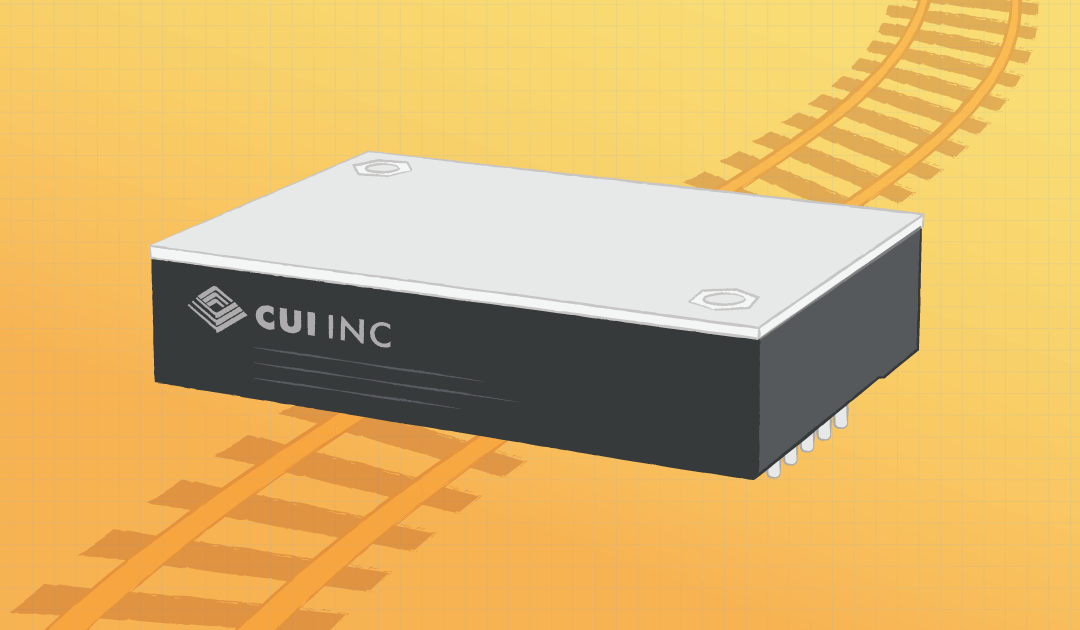

Die in Bahnanwendungen am häufigsten verwendeten Batteriespannungen sind 24 V, 48 V, 72 V, 96 V und 100 V. Aufgrund der unvermeidlichen Spannungseinbrüche und

-spitzen, die durch den Bedarf mehrerer Bordsysteme verursacht werden, variieren diese Werte stark. EN 50155 legt fest, dass diese Werte das 0,7- bis 1,25-Fache des Nennwerts betragen dürfen, wobei auch stärkere transiente Schwankungen von 0,6 bis 1,4 (Nennwert) (für eine Dauer von bis zu 100 ms) akzeptabel sind.

Elektromagnetische Verträglichkeit

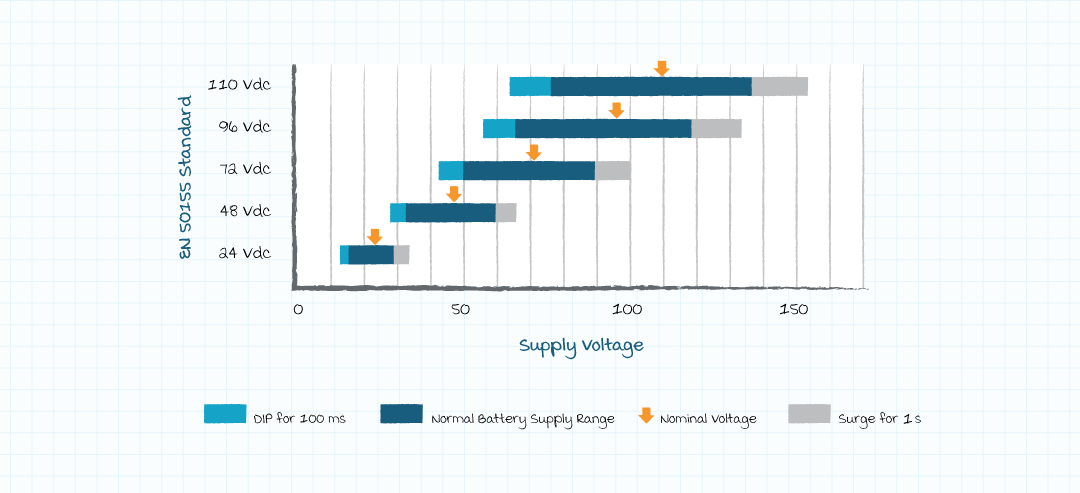

Die Anforderungen an die elektromagnetische Verträglichkeit (EMV) von elektrischen Geräten werden durch die Art und Weise definiert, wie sie mit der äußeren Umgebung interagieren. Diese Schnittstellen werden als Ports bezeichnet (Abbildung 1). Verschiedene Ports haben unterschiedliche EMV-Anforderungen.

Für Batterieanschlüsse gibt es keine Grenzwerte für leitungsgebundene Emissionen im Frequenzbereich von 9 kHz bis 150 kHz. Die gleichen EMV-Anforderungen gelten für batteriebezogene, Signal- und Kommunikations-, Prozessmess- und

-steuerungsanschlüsse und sind in EN 50121-3-2 festgelegt. Anforderungen an die Störfestigkeitsprüfung sind in der EN 50121-3-2 festgelegt.

Mechanische Stöße und Vibrationen

Elektronische Geräte müssen den Erschütterungen und Vibrationen, denen ein Zug im regulären Betrieb ausgesetzt ist, ohne Leistungseinbußen standhalten können. Diese Stufen können vom Zuganbieter festgelegt werden. Andernfalls müssen sie die Anforderungen der EN–61373Kategorie 1, Klasse B (Tabelle 1) erfüllen.

| Leistung | {1} / {1} |

|---|---|

| Vibrationen | Kategorie < 0,3 kg 5–150 Hz 5 g |

| Stöße | Längs-/Trans.-/Vert.-Achse 5g/3g/3g 30mS/30mS/30mS |

Temperatur und Luftfeuchtigkeit

Elektronische Geräte müssen so ausgelegt sein, dass sie in einer Reihe von verschiedenen Temperaturklassen (Tabelle 2) mit ihrer vollen Spezifikation arbeiten.

- Fahrgast- und Fahrerräume fallen unter die Klassen OT1 und OT2 (mit einer Standard-Bezugstemperatur von +25 °C).

- Die Klassen OT3 und OT4 umfassen Geräte in technischen Schränken (mit einer Standard-Bezugstemperatur von +45 °C).

- OT3 ist die Standardklasse.

| Klasse | Betriebstemperaturbereich (°C) |

|---|---|

| OT1 | -25 bis 55 |

| OT2 | -40 bis 55 |

| OT3 | -25 bis 70 |

| OT4 | -40 bis 70 |

| OT5 | -25 bis 85 |

| OT6 | -40 bis 85 |

Isolationsspannung

Diese technischen Daten stellen sicher, dass die Leiter in den Netzteilen über eine ausreichende elektrische Isolierung und einen ausreichenden Abstand verfügen, so dass Leckströme und elektrische Lichtbögen kein Problem darstellen. Dieser Test besteht aus zwei Teilen:

- Eine Isolationswiderstandsmessung, die bei 500 VDC durchgeführt wird. Der erforderliche Mindestisolierwiderstand beträgt 20 Megaohm.

- Der zweite Teil ist eine Spannungsfestigkeitsprüfung (Tabelle 3). Die Spannung wird langsam (in der Regel in 10-Sekunden-Intervallen) bis zum Maximalwert erhöht. Die Spannung wird für zehn Sekunden oder eine Minute aufrechterhalten, je nach Zweck der Prüfung.

| Fahrzeug-Batterie (V) | Isolationsanforderung VAC (50 Hz) / DC |

|---|---|

| 24 | 500/750 |

| 48 | 500/750 |

| 72 - 125 | 1000/1500 |

| 125 - 315 | 1500/2200 |

Zertifizierte Stromversorgungslösungen

Die isolierten DC/DC-Wandler der PRQE-Serie von CUI Inc. erfüllen die EMV-Prüfungsanforderungen der EN 50121-3-2 und wurden entwickelt, um Systeme zu ermöglichen, die die EN 50155 in Bahnanwendungen erfüllen.

Diese Quarter-Brick-Wandler, die auch über eine EN 62368-1-Zertifizierung verfügen, werden in einer Reihe von Leistungsstufen angeboten, darunter 50 W und 75 W. Diese Geräte sind in einem vollständig gekapselten Gehäuse aus Aluminiumlegierung mit einem schwarzen Kunststoffboden untergebracht und verfügen über die Brennbarkeitsklasse UL 94V-0. Sie haben einen Wirkungsgrad von bis zu 94 %, einen ultraweiten 4:1-Eingangsbereich und bieten Schutz vor Überstrom, Überspannung und Kurzschluss.

Die Wandler der PRQ-Serie sind in einem DIP-Gehäuse mit oder ohne Kühlkörper oder Grundplatte erhältlich. Abgesehen von Bahnanwendungen sind sie ideal für Daten-, Telekommunikations-, Robotik- und Industrieanwendungen – überall dort, wo Sie eine große Menge an Strom von einem Gerät in einem kompakten Design benötigen.

Produktauswahl, Sicherheit und Konformität

Haben Sie irgendwelche Kommentare bezüglich dieses Beitrags oder Themen, die wir in der Zukunft besprechen sollten?

Senden Sie eine E-Mail an powerblog@cui.com